Powerful Tools for Data-Driven Factory Automation Operations

Today’s Factory Automation industry is undergoing rapid digital transformation. Smart sensors, digital control devices, advanced drives and controls generate a constant stream of production and performance data. Red Lion has the smart, scalable technology to ensure that mission-critical industrial data is efficiently accessed, securely and safely connected with critical analytical systems and visualized to provide actionable, real-time insights on ways to improve automation performance.

Resources

White Paper

⤓ Download

Case Study

⤓ Download

Whitepaper

⤓ Download

OT Integration

White Paper

⤓ Download

Application Note

⤓ Download

Application Note

⤓ Download

Red Lion Field Application Engineer

How To Unlock the Full Potential of Your Automation Data

Red Lion's industrial portfolio improves access to production data, SCADA systems and cloud-based analytics, enhances industrial network connectivity with advanced Ethernet switches and remote access platforms and delivers clear, actionable data to the factory floor with panel meters and HMI visualization products.

Scalable & Flexible

Automated manufacturers value the ability to modify their production systems to support new products or markets. They need data access and connectivity systems like the FlexEdge® Intelligent Edge Platform and Secure Remote Access products that make it easier to integrate new production systems, connect widely separated facilities and make efficient, flexible use of manufacturing data.

Rugged & Reliable

Many factories operate on 24/7 cycles – so when critical plant devices are down, costs mount up. Our industrial switches, edge computing platforms and HMIs are engineered to operate reliably for years in the field, including alarms to indicate when devices might need replacing as well as self-healing capabilities for rapid restoration.

Secure Solutions

Every manufacturer invests time and resources to secure their operations from ransomware and hackers. Through technology such as our Crimson software and our RA10 industrial firewall, we provide multiple tools to help protect applications from attacks by segmenting industrial networks into logically segregated units.

Digital Transformation

Smart, adaptive and future-proof automation platforms leverage the power of real-time industrial data to guide day-to-day operations and long-term planning. Red Lion’s full portfolio of access, connect and visualization technologies help deliver the full power of industrial data and digital transformation to manufacturers.

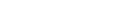

Bridging the IT/OT Gap in Factory Automation

Manufacturers seeking to fully utilize their industrial data need to move data more easily between the OT and IT domains. Red Lion’s industrial data portfolio includes protocol conversion capabilities, advanced cybersecurity, high-performance managed Ethernet switches and remote access systems – technology designed to bring complex, multi-vendor environments into fully integrated factories.

Red Lion’s Crimson® Software :

Delivering Real Time Monitoring of Critical Applications

Crimson software is a remarkable programming platform that delivers a powerful set of drag-and-drop configuration, visualization, control, data logging tools and remote access.

- Convert up to 20 protocols simultaneously from over 300 supported drivers

- An all-in-one environment that eliminates the need for multiple configuration tools

- Connect to most MQTT cloud servers for data transfer over internet or for LAN communication via OPC-UA and/or SQL

- Rapidly build graphic interfaces with comprehensive image library of over 5,000 industrial graphics

- Capabilities using full-featured C-type syntax programming environment to support advanced math, local variables, pass parameters, calls, return values and more

- Ability to remotely access applications through OpenVPN, IpSec and GRE tunneling protocols